Our services

Our services

Recognising the need for companies to focus on their core business objectives, Bio-Steril offers a comprehensive range of tailor-made services to clients in various sectors, including medical devices, cosmetics, pharmaceuticals, veterinary and more.

- Regulatory consulting

- Process development and optimisation

- Product formulation (including gels and liquids)

- Syringe and vial filling

- Steam sterilisation and steam decontamination

- Visual inspection

- Labelling (including UDI serialisation)

- Sterile and blister packaging

- Final packaging

- Storage, shipping and logistics

- ISO 7 laboratory rental

BIO-STERIL stands for

Over 20 years of specialised experience in steam sterilisation: With extensive expertise in steam sterilisation of complex and heat sensitive products, BIO-STERIL ensures a high quality service in accordance with ISO 17665-1 standards and ISO 13485 processes.

Expertise in manual and automated production: From small batch manual production to medium and large batch semi or automated production, we offer flexibility and expertise across all production scales.

Adaptability to specific needs: Our teams at Bio-Steril are adept at tailoring our services to the unique requirements of each project, taking into account regulatory constraints and delivering customised solutions in a timely manner.

Commitment to quality and safety: Bio-Steril is committed to quality and safety in all processes, meeting customer expectations and adhering strictly to industry standards. Since 2009, we are ISO 13485 certified.

Comprehensive support: Our dedicated teams provide comprehensive support to customers, assisting them through validation processes at every stage of product manufacture, from design to routine production.

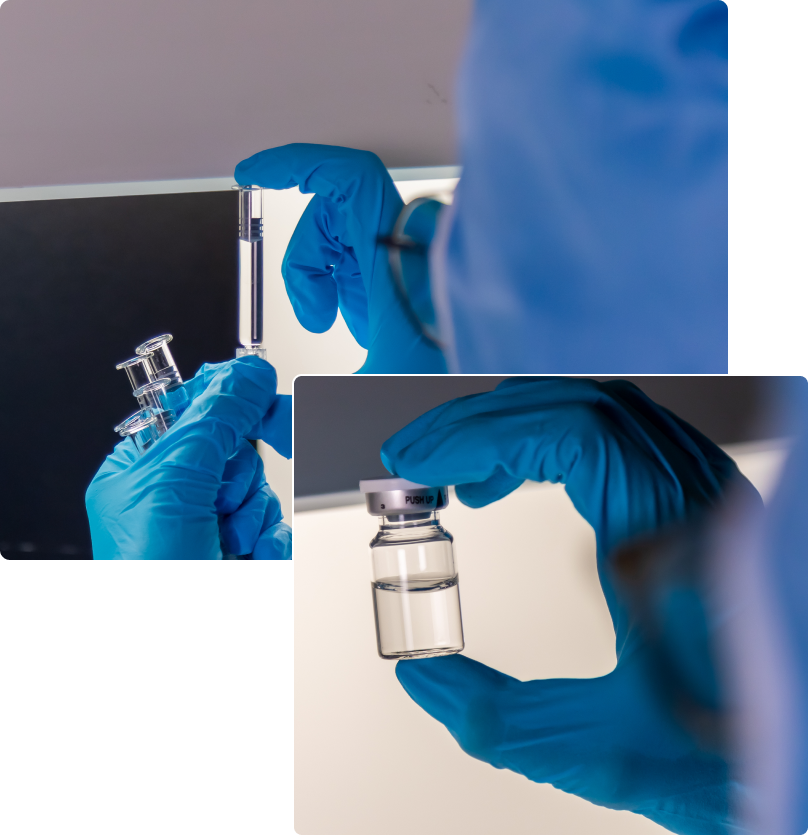

FILLING OF SYRINGES / VIALS

With over 15 years of experience in manual and semi-automatic filling, Bio-Steril offers the best solutions for your syringe or vial filling project. We handle all types of products, from liquids to highly viscous substances.

Our expertise allows us to adapt to your constraints, whether technical, batch size (small or large) or environmental/regulatory requirements.

At Bio-Steril, we pride ourselves on our expertise and technical capabilities to ensure the quality and safety of the medical devices we produce on behalf of our customers.

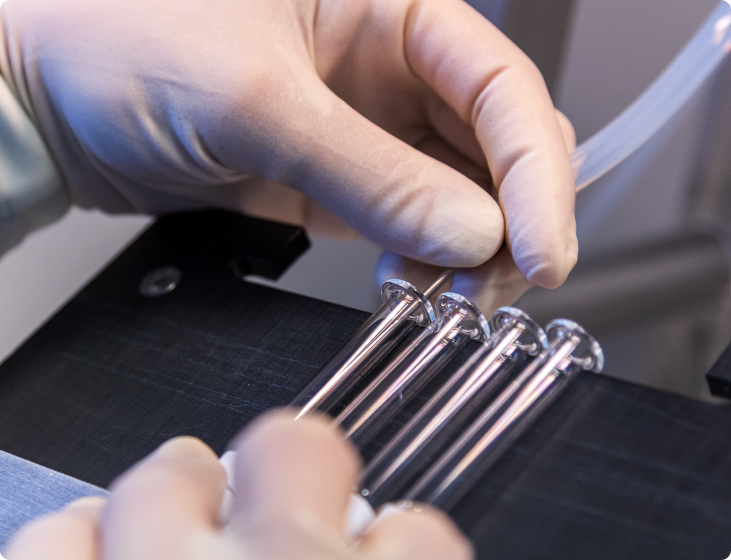

Manual Filling

Bio-Steril has developed a manual syringe filling and capping system that allows very small quantities of product to be handled. Performed in ISO 7 cleanrooms under ISO 5 flow, this capability allows our customers to control the quantities of product used in their product development. This is also important at key stages of preclinical and clinical trials.

Our capabilities can be applied to a wide range of products, from liquids to highly engineered gels.

Our teams are trained to adapt to different product viscosities as well as any specific customer requirements.

Automatic filling

Bio-Steril offers automatic or semi-automatic filling and capping solutions for syringes and vials. Our equipment, which is more suitable for medium and large scale production, can handle product volumes from 1L to 60L.

Larger volumes can be considered depending on the project, please contact us if required. Bio-Steril is equipped with semi-automatic vial filling machines (6R, 10R, etc.) which allow us to handle medium sized batches while ensuring the highest quality and safety standards.

This process is performed in ISO 7 cleanrooms under ISO 5 flow. and is particularly suitable for batches of 1000 to 7000 units. This filling solution offered by Bio-Steril maintains a good balance between productivity, quality and process safety, ensuring consistent quality of packaged products. This production step is validated according to the customer's regulatory and technical requirements and the applicable standards in their reference.

STEAM STERILISATION

L’expertise historique de BIO-STERIL porte sur la stérilisation à façon sur mesure.

Avec 20 ans d’expérience dans le développement de cycles de stérilisation pour tous types de produits et matériaux, BIO-STERIL est spécialiste dans ce domaine. Notre personnel expérimenté et qualifié sait travailler en étroite collaboration avec nos clients afin de développer des cycles de stérilisation adaptés à chaque projet.

STEAM STERILISATION

Revendiqué selon

ISO 17665:2024

Our site is equipped with two 600L air/steam autoclaves, allowing us to perform standard cycles (e.g. 121°C for 15 minutes) as well as high tech cycles with rapid heating and cooling (e.g. 131°C for 1 minute).

These capabilities are applicable to technical loads of contained products (vials, syringes, etc.) and equipment. For each project, Bio-Steril will assist you in developing the most appropriate cycle for your needs, both technically and from a regulatory perspective.

We support you in the validation process to claim the sterile status of your products and equipment. We are fully aware of the importance of sterilisation in the medical device manufacturing process and are fully committed to providing our customers with the best services and solutions while complying with the standards associated with this activity.

This is why Bio-Steril is ISO 13485:2016 certified by LNE/GMED and works in accordance with ISO 17665-1 for steam sterilisation.

le métier de stérilisation

VISUAL INSPECTION

Bio-Steril offers its customers extensive experience in this activity. We can help you develop specific defect libraries for each of your projects. The visual inspection step involves verifying, in a controlled environment, the conformity of the physical integrity and cleanliness of the products. Visual inspection is a very important and essential step for implantable medical devices or those used in patient contact applications.

Contrôle visuel - Mirage

Bio-Steril offers its customers extensive experience in this activity. We can help you develop specific defect libraries for each of your projects. The visual inspection step involves verifying, in a controlled environment, the conformity of the physical integrity and cleanliness of the products. Visual inspection is a very important and essential step for implantable medical devices or those used in patient contact applications.

These inspections may include, but are not limited to

- Label verification: Ensuring legibility and conformity of information, correct placement and absence of data alteration.

- Packaging inspection: Checking for damage, physical signs of alteration or contamination.

- Device inspection: Ensuring that the medical devices themselves are free from damage such as cracks, scratches or other deterioration.

- Contents inspection: Eliminating any risk of foreign objects, air, or volume defects, if applicable.

This step ensures the safety of device use and the quality of care ultimately provided to patients. Our visual inspection team is trained to identify all types of defects according to customer specifications, taking into account the criticality of each project. Our expertise allows us to manage defects based on the different types of products inspected. We maintain rigorous tracking of each batch produced and can provide statistical tracking of rejects. This approach allows our customers to monitor trends and anticipate process deviations through analysis.

In summary, at Bio-Steril we implement visual inspection processes tailored to the specifications and criticality of each project. Our know-how and expertise in this field guarantees quality for our customers.

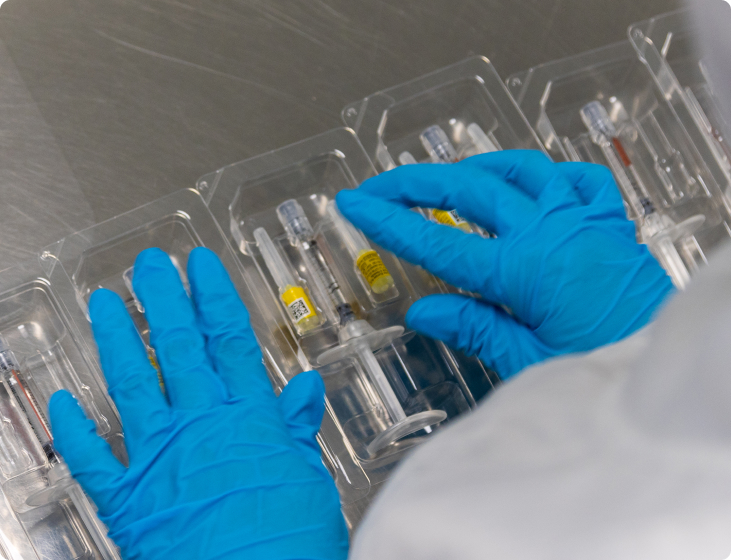

NON-STERILE PACKAGING

UDI labelling, kit assembly, preformed blister packaging... From automated competence to manual expertise.

BIO-STERIL can handle both large and small series. BIO-STERIL is an expert in the production of medical devices and offers a comprehensive service from primary packaging (before sterilisation) to final packaging of medical devices. This can include activities such as UDI labelling, kit assembly, blister packaging and final boxing. We have extensive automated capabilities to handle large volumes, as well as manual expertise to handle small batches.

Manual packaging

1. Flexibility: Manual packaging allows us to adapt to the specific needs of each product, taking into account the characteristics of each medical device.

2. Improved quality control: Manual packaging allows better quality control, as it is easier to detect any defects or errors when packaging is done by hand.

3. Production in small batches: Manual packaging is more suitable for the production of small batches of medical devices, which is often the case for innovative or low-volume products.

4. Customised production: Manual packaging allows the production of customised medical devices based on the specific needs of the customer.

5. Customisation: Manual packaging allows medical devices to be customised to meet specific patient needs.

Automatic packaging

Automatic packaging of medical devices has several advantages:

1. Increased productivity: Automatic packaging leads to increased productivity compared to manual packaging due to the speed and efficiency of the machines.

2. Error reduction: Automated packaging reduces the potential for human error as it is less prone to handling or packaging errors.

3. Consistency of quality: Automated packaging ensures better quality consistency as machines are programmed to follow precise and repeatable packaging protocols.

4. High volume production: Automated packaging is more suitable for the production of large volumes of medical devices, which is often the case for common products and high-volume

5. Standards compliance: Automated packaging ensures compliance with medical standards and regulations by maintaining quality and safety standards.

Labelling of

syringes and vials

- Name and address of the manufacturer

- Trade name and general product description

- Reference and/or batch number

- Manufacturing and/or expiry date

Note: The presence of UDI (Unique Device Identification) codes, such as 2D matrix or barcode, has been mandatory for medical devices since September 2020.

Blister Packaging

An important step in the production of medical devices in pre-formed blisters, blister sealing protects the products inside from moisture, light and external contamination.

To ensure product quality and safety, Bio-Steril recommends a process to validate the quality of blister sealing. This process is internally controlled.

The sealing parameters (temperature, pressure, time, etc.) are defined to ensure the best sealing for the materials used.

Bio-Steril routinely and systematically checks the sealing parameters to ensure the integrity and safety of the processes defined during validation.

It is important to note that Bio-Steril allows its customers to verify that the sealing parameters meet their requirements and ensure the integrity and safety of their medical devices.

Final packaging

The final production step, final boxing, can be carried out in two ways: Manual or automatic boxing, each with its own advantages.

Manual boxing: Particularly suitable for pre-formed and/or complex kits and for small series, this operation is not suitable for very large series. It is also recommended for kits with multiple components that are difficult to automate.

Automatic boxing: Bio-Steril is equipped with a cartoning machine designed for medium and high volume packaging.

This equipment is suitable for medical devices. It ensures the insertion of regulatory notices, tamper-evident labels and traceability labels, all with excellent packaging quality and productivity, guaranteeing an optimised production time.

Depending on your projects, BIO-STERIL can offer you one of these options to ensure optimal packaging of your medical devices.